Introduction

The automotive industry is under immense pressure: shorter product cycles, tighter tolerances, and electrification trends are reshaping manufacturing. In this environment, efficiency and precision are survival tools.

This case study explores how a mid-sized automotive supplier adopted self-centering vises across its cnc with 4th axis lines, achieving remarkable gains in productivity, quality, and profitability.

Company Background

- Company: AutoForm Components, Ohio, USA

- Sector: Tier-2 automotive supplier

- Products: Suspension arms, EV battery trays, brake system components

- Challenge: Increasing demand for small-batch customized components while maintaining cost competitiveness

The Problem

- Long Setup Times

Each new part required manual vise adjustments—10–20 minutes per setup. With 40+ job changes per week, lost productivity was significant. - High Scrap Rates

Misalignment errors caused ~8% scrap in aluminum EV parts. - Operator Variability

Skilled operators could achieve good results, but outcomes varied with less experienced staff.

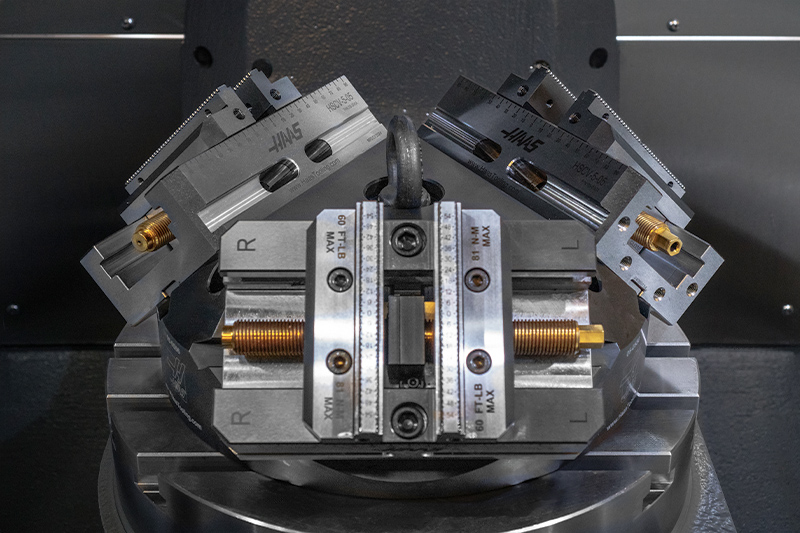

The Solution: Self-Centering Vises

In 2023, AutoForm piloted self-centering 5th axis vises on 10 CNC machines. Within six months, they expanded the solution plant-wide.

- Type: Hydraulic self-centering vises

- Integration: Robot-loaded production cells

- Jaw Customization: Quick-change modular jaws for different component families

Results

- Setup Time Reduction

- Old average: 15 minutes per changeover

- New average: 5 minutes

- Time saved per week: ~400 minutes (6.5 hours)

- Old average: 15 minutes per changeover

- Scrap Reduction

- Before: 8% scrap rate

- After: 2% scrap rate

- Annual savings: ~$250,000 in materials

- Before: 8% scrap rate

- Operator Training Simplified

- New staff trained in days instead of weeks

- Consistent results regardless of operator skill

- New staff trained in days instead of weeks

- Machine Utilization

- Overall increase of 10%

- Equivalent to adding an extra machine without capital investment

- Overall increase of 10%

Additional Benefits

- Improved Quality Control: Symmetric clamping ensured repeatability for tight-tolerance parts.

- Customer Satisfaction: Faster delivery and fewer defects strengthened supplier relationships.

- Sustainability Impact: Reduced scrap aligned with corporate ESG goals.

Lessons Learned

- Invest in Modular Jaws

Flexibility across different components is key. - Plan Integration with Robots

Automation works best when paired with self-centering clamping. - Don’t Underestimate Training

Operators must understand how to maintain the fixturing clamps for long-term ROI.

Conclusion

For AutoForm Components, self-centering vises weren’t just a tooling upgrade—they were a strategic enabler of competitiveness in the automotive sector.

By cutting setup times, reducing scrap, and enabling automation, they unlocked productivity equivalent to adding new machines—without the capital expense.

The takeaway? In the automotive industry, where every second and every part counts, workholding innovation can drive transformation as much as any new machine or software system.